PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Tightening Assurance System > Tightening assurance system (Pokayoke)

Tightening assurance system (Pokayoke)

Human tightening errors are the most common cause of trouble involving bolt tightening. We supply wired and wireless devices designed to prevent human tightening errors by controlling tightening count, and marking devices that automatically leave evidence on the heads of bolts and small screws indicating they have been tightened properly to the set torque.

AC3

Pneumatic motor mounted on torque wrench, for work from provisional tightening to final tightening using just the one tool.

For assembly and mass-production.

R-CM

Three different wireless modules can be used, and you can switch them on your own. They can be used on a number of different wireless devices, reducing cost.

Wireless Pokayoke (error proofing) torque wrench signal reception to prevent missed tightening

Wireless Pokayoke (error proofing) torque screwdriver signal reception to prevent missed tightening

Click type wireless data transfer torque wrenches FD/FDD and FDD-AD data reception

RTDLS/RNTDLS

Error-proofing (Pokayoke) torque driver with limit switch output to eliminate missed tightening.

Pokayoke (tightening error-proof)

TPC/TPC2

The protocol converter connects Tohnichi products to systems that have other configured protocols

It establishes a system that can use a variety of tools to match the output format of Tohnichi products with production line nutrunner protocols.

It establishes a system for converting the output of Tohnichi’s Pokayoke (error-proofing) R-CM receiver to Ethernet.

Nutrunner backup system

It provides torque control for nutrunner tasks in difficult-to-reach confined spaces.

It is used for preventing human tightening errors (Pokayoke) and managing tightening torque data.

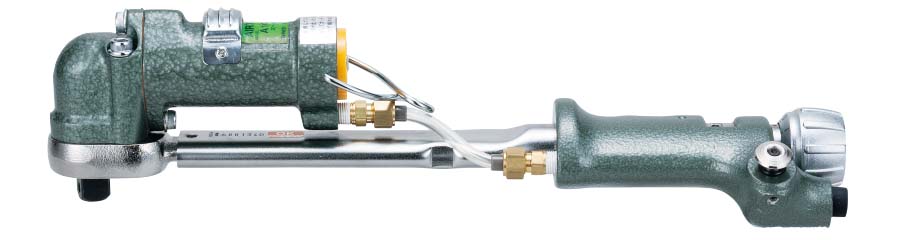

A3/A4

Air motor mounted on torque wrench allows for all functions from provisional tightening to final tightening in one tool. On May 21, 2024, A10N3 and ALS10N3 were upgraded to the lighter, more compact A10N4 and ALS10N4, while A25N3 and ALS25N3 were similarly upgraded to the A25N4 and ALS25N4.

For assembly and mass-production.

IO-CM

Tohnichi has doubled the number of input/output contact points on the R-CM Wireless Receiver with Interchangeable Modules.

Expanded functionality for the wireless Pokayoke (error proofing) system

RTDFH / RNTDFH

Prevents human tightening errors by wireless (cordless). Wireless communication range and battery life were both significantly increased for the RTDFH/RNTDFH in March 2024.

Pokayoke (tightening error-proof)

BZ-CM

Increased buzzer alert volume and LED surface area on the R-CM Wireless Receiver with Interchangeable Modules. This makes it easy to recognize judgment results from a considerable distance.

Use of the R-CM Wireless Receiver with Interchangeable Modules to check Pass/Fail results.

MNTD

A world first! When the set torque is achieved, it automatically marks evidence of proper tightening on the heads of small screws and bolts. It determines whether tightening has been missed by detecting the presence or absence of marks, at the end of the manufacturing process and after shipping. MNTD series Error-proofing (Pokayoke) torque drivers mark small screws and bolts after tightening, as a human tightening error countermeasure.

Torque control for bolts and screws

Prevents human tightening errors (Pokayoke)

SB-FH2

It is easy to wirelessly perform data transfer settings on Pokayoke (error proofing) transmitters and receivers.

Telecommunication settings performed on the R-CM Wireless Receiver with Interchangeable Modules

Telecommunication settings performed on the FHM/FH, etc., for wireless Pokayoke (error proofing) torque wrenches

Telecommunication settings performed on FD/FDD and FDD-AD click type data transfer torque wrenches

CNA-4mk3

The error-proofing (Pokayoke) counter controls the number of tightening operations to prevent human tightening errors.

For tightening count verification, and production management.

HA/HAC/HACQSPDY

For battery-charge type for excellent workability. Semi-automatic electric torque wrenches let you use your existing torque wrench tester for calibrating.

Cell production and assembly work on a sub-line

Tightening Data Management System

Provides evidence in the form of tightening torque data

R-BT

This Bluetooth receiver receives tightened-to-completion signals from the HAC series of battery-operated semi-automatic torque wrenches, and outputs signals to devices such as the CNA-4mk3 error-proof count checker. It can receive torque data from HACQSPDY devices that transmit tightening torque data, and from the PTA-BT series of battery-operated fully automatic torque drivers. Use it to easily build a tightening data management system.

Receives tightened-to-completion signals from battery-operated semiautomatic torque wrenches in the HAC series.

Tightening assurance system (Pokayoke) to prevent human tightening errors.

Tightening data management system using HACQSPDY or PTA-BT.

SB-FH256

The various settings for FH wireless Pokayoke (error proofing) transmitters and receivers are done wirelessly. * The SB-FH256 was upgraded to the SB-FH2 to accommodate R-CM receiver upgrades.

Make/change setting on group channel, ID, etc. for FH wireless torque wrenches.

A

The pneumatic motor mounted on the torque wrench permits uninterrupted work from provisional tightening to final tightening. The A series was upgraded to the A3 series on May 21, 2018.

For assembly and mass-production.

I/O-FH256

One receiver can recognize a maximum of four torque wrenches, when generating contact outputs. * The I/O-FH256 was upgraded to the IO-CM to accommodate changes made when the R-FH256 receiver was upgraded to the R-CM.

The I/O-FH256 was upgraded to the IO-CM to accommodate changes made when the R-FH256 receiver was upgraded to the R-CM.

Maximum 4 contacts selectable from R-FH256.

AC2

The pneumatic motor mounted on the torque wrench permits uninterrupted work from provisional tightening to final tightening. The AC2 series was upgraded to the AC3 series on May 21, 2018.

For assembly and mass-production.

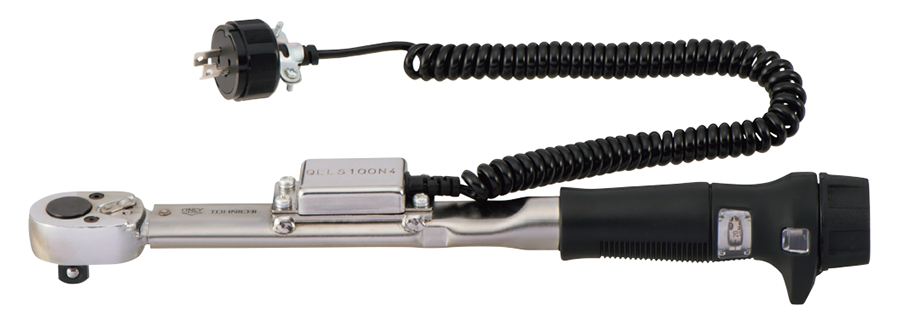

QLLS/CLLS/PQLLS/PCLLS/TiQLLS/YCLLS

Pokayoke torque wrench with limit switch output to eliminate missed tightening.

Pokayoke (tightening assurance).

QSPLS/CSPLS/QRSPLS/SPLS/SPLS-MH/RSPLS/RSPLS-MH/SPLS-N

Pokayoke torque wrench with limit switch output to eliminate missed tightening.

Pokayoke (tightening assurance).

QSPCAMS/QSPCALS

A torque wrench that prevents 3 problems: under-tightening, over-tightening, and other human tightening errors.

Prevents under-tightening, over-tightening, and other human tightening errors.

FH

The FHM/FH series was integrated with the T-FHP series in March 2024, becoming the FH series. It supports wireless Pokayoke (error proofing) torque wrenches ranging from 0.3 N・m to 420 N・m. The button battery-powered compact T-FHPM/T-FHLS transmitter now offers significantly greater wireless communication range and longer battery life.

Prevents human tightening errors (Pokayoke)

QSPCAFH

The QSPCAFHP and QSPCAFHLSM series were integrated in March 2024 to create the QSPCAFH series of torque wrenches with “triple no problem” design to prevent insufficient tightening, overtightening, and human tightening errors. Battery life has improved significantly, and wireless communication range is greater than that of the older QSPCAFHP. Compatible with rotary slip wireless Pokayoke (error proofing) torque wrenches ranging from 2 N・m to 70 N・m.

Pokayoke system to prevent under-tightening, over-tightening and missed tightening

CSPFHW

Achieves high reliability Pokayoke (error-proofing) (eliminate missed tightening) with its double tightening detection function. Sales of the improved model began in March 2024.

Prevents human tightening errors (Pokayoke)

Double Tightening Prevention

T-BLA/QLBLA

Now also available in the U.S., Canada, and Mexico. Torque wrench with wireless “pokayoke” error proofing to prevent missed tightening, using the Energy Harvest system for solar power generation. No need to change batteries, eliminating battery expense and bothersome battery replacements. The R-BL receiver has been upgraded to the R-CM, which is downward compatible.

Pokayoke error-proof system helps prevent human error when tightening bolts and screws

Assembly line interlock control system using tightening count control

Pokayoke (error-proof) system / Tightening control system

MPQL/MQL

Pokayoke (error-proofing) marking torque wrench. Lets you make direct visual checks for bolt tightening errors.

Pokayoke (tightening assurance).

MPCL

This open-end interchangeable head pre-lock marking torque wrench comes with the ever-popular torque scale.

Nut torque control.

Prevents human tightening errors (Pokayoke).

Tightening piping on hydraulic / pneumatic devices.

Construction projects involving electrical / telecommunication / power facility / air-conditioning equipment / natural gas installations, etc.

Useful in confined areas where MPQL/MQSP cannot be used for tightening hex bolts.

CMQSP

A mark is made on the tightened cap screw and an adjacent location on your work. This lets you check for subsequent loosening. A marking torque wrench for tightening cap screws, which prevents human tightening errors.

Pokayoke (tightening error-proof)

MQSP

Pokayoke (error-proofing) marking torque wrench. Lets you make direct visual checks for bolt tightening errors.

Pokayoke (tightening assurance).

MCSP

Interchangeable open end head marking torque wrench. When the set torque is reached, the wrench automatically leaves a mark on nuts (bolts) to provide evidence of proper tightening.

Nut torque control.

Prevents human tightening errors (Pokayoke).

Tightening piping on hydraulic / pneumatic devices.

Construction projects involving electrical / telecommunication / power facility / air-conditioning equipment / natural gas installations, etc.

Useful in confined areas where MPQL/MQSP cannot be used for tightening hex bolts.

FD/FDD

Transmits tightening torque data wirelessly at the click moment. Pass/fail judgment is known close at hand, providing excellent workability. The FDD’s double tightening detection ensures even greater on-the-job reliability. The R-FHD receiver has been upgraded to the R-CM.

Tightening Torque Data Management

Pokayoke (tightening error-proof)

FHM/FH

The FHM/FH series was upgraded to the FH series in March 2024. This lets you use the transmitter to check and switch between new and old communication modes with a transmitter. Another plus: the T-FHSLS256 features longer battery life and greater communication range.

Prevents human tightening errors (Pokayoke)

T-FHP

Wireless Pokayoke (error proofing) transmitter for compact torque wrenches satisfies keen expectations. The T-FHP was integrated with the FH series in March 2024. It lets you switch to new communication mode for longer battery life and greater communication range.

Tightening count control for pokayoke prevention of human tightening errors

QSPCAFHP/QSPCAFHLSM

Torque wrenches with “triple no problem” design to prevent insufficient tightening, overtightening, and human tightening errors. *QSPCAFHP/QSPCAFHLSM were integrated in March 2024 to create the upgraded QSPCAFH series. It lets you switch to new communication mode for longer battery life and greater communication range.

Pokayoke system to prevent under-tightening, over-tightening and missed tightening

FH256MC

Cordless. Designed to prevent missed tightening. The FH256MC transmitter has been upgraded to the FHM/FH, and the R-FH256 receiver has been upgraded to the downward compatible R-CM.

GLOBAL HOME

GLOBAL HOME