PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Power Torque Tools > Power Torque Wrench > HA/HAC/HACQSPDY

HA/HAC/HACQSPDY

Assembly

Pre-Lock

Electric Power

Torque Graduation

Wireless

Re-chargeable

For battery-charge type for excellent workability. Semi-automatic electric torque wrenches let you use your existing torque wrench tester for calibrating.

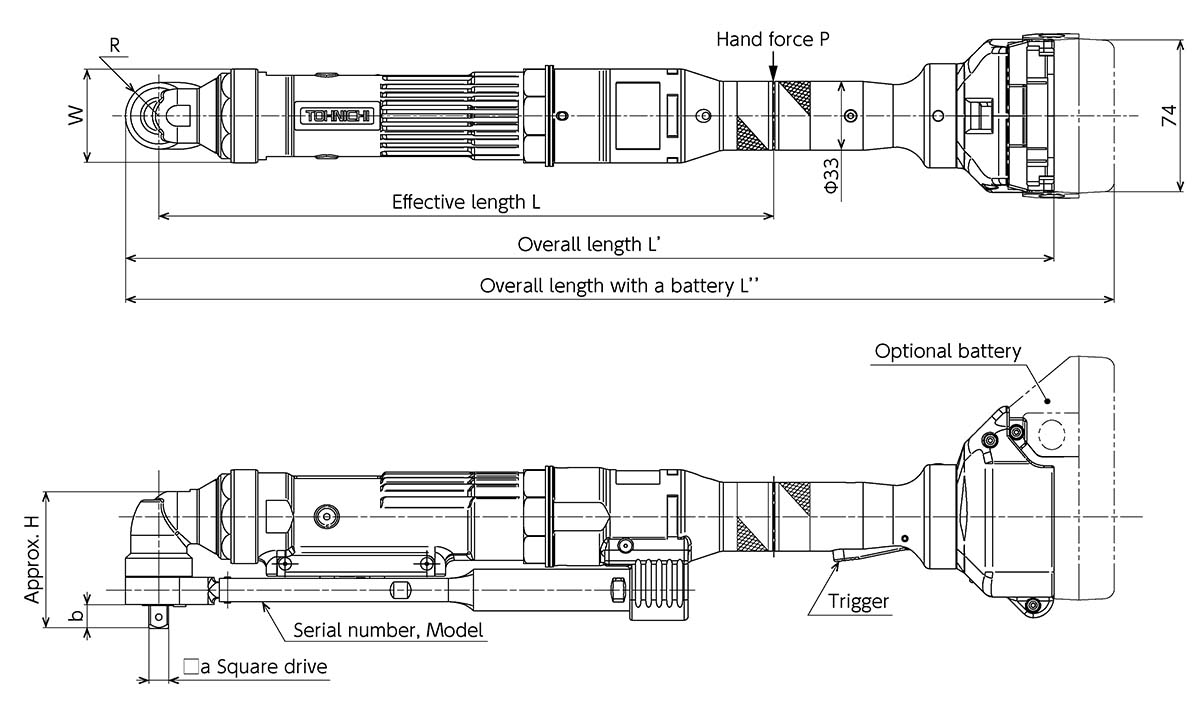

HAC100N battery-operated semi-automatic electric torque wrench (* Note: Shown attached to optional large-capacity battery)

Greater choice in our series lineup. Compact, lightweight HA25N (* shown connected to optional lightweight battery)

Example of use of HAC series tools

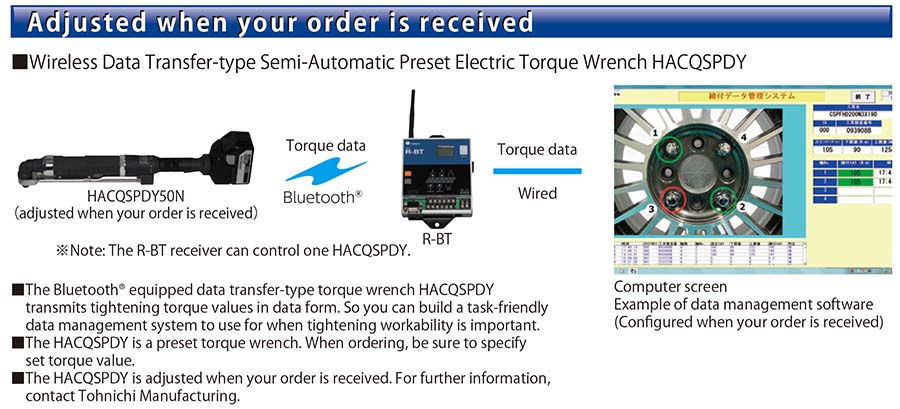

The HACQSPDY/HACQSPDY series is ideal for the Tightening Assurance System, which transmits tightening torque data wirelessly with Bluetooth®.

Application

- Cell production and assembly work on a sub-line

- Tightening Data Management System

- Provides evidence in the form of tightening torque data

Features

- Far cheaper than an electric hand nutrunner, yet offers high precision torque control.

- Generally, provisional tightening is done with an electric screwdriver, and then final tightening is done with a torque wrench. But now both provisional and final tightening can be done with a single tool. With “No Wasted Time” there’s no need to switch tools.

- Provisional tightening is done with a labor-saving brushless electric motor. Final tightening can be done with a torque wrench with ±3% torque control accuracy.

- Maintenance-free! Uses a durable brushless motor, so there’s no need to ever change brushes.

- Cordless! Rechargeable battery powers the electric motor for provisional tightening. No power cable for DAC, so no worry about reduced workability or failure caused by a cut cable.

- Pokayoke (error proofing) is cordless too! Tightened-to-completion signals are transmitted by Bluetooth®, making it easy to build a Pokayoke system to prevent human tightening errors. Cordless operations result in excellent workability, with no worry about cords getting cut.

- No need for special controller connection. Cordless, so no worries when moving about on the production line, and no need to repair cords.

- Provisional tightening possible with three-step torque adjustment. With a Bluetooth®-equipped computer, setting software lets you change provisional tightening torque. (* Note: Software available for downloading free of charge.)

- The software lets you change tightening mode. The setting software can also switch from one mode to the other. Tightening mode 1: For provisional tightening that connects multiple flange bolts. Tightening mode 2: After provisional tightening, if final tightening is missed the next provisional tightening cannot be done. (* Note: Software available for downloading free of charge.)

- Able to calibrate with a torque wrench tester currently in use. No need for a special calibration device, so traceability at the control level is equal to that achieved with a torque wrench.

- The compact, lightweight HA25N was launched on the market on January 25, 2016.

- HAQSPDY/HACQSPDY Series models are capable of sending tightening torque data over wireless connections (Bluetooth(R)), and can be ordered by request only. With the “TDMS/TDMSHT” (Ver. 2.00 or higher) products launched in March 2017, users can construct tightening data management systems.

- Except for some products, the HA/HAC/HACQSPDY series are compliant with ISO 6789:2017 starting January 2022. For more information, see the technical data “Initiatives for ISO 6789:2017” at the bottom of the screen.

- Can use wireless Bluetooth® technology to manage HACQSPDY tightening data. * Use Excel® on your computer to manage data received via the free DtRcv (Data Receiver) software. DtRcv is included in software under the screen. (Setting software included.)

Demonstration video

Product info: HAC battery-operated semi-automatic electric torque wrenches

Specifications

[N・m] |

||||||||

BOLT |

||||||||

[mm] |

||||||||

with BATTERY |

||||||||

rotation speed is about 850 rpm. |

||||||||

①HA25N(only body) ②HAC50N+BP1830C(body+battery) ③HAC100N+BP1850C+BC18YSL3(body+battery+battery charger) ④HAC140N+BP1830C+BC18YSL3+R-BT(body+battery+battery charger+bluetooth® receiber) |

||||||||

Notes

HA/HAC conforms to telecommunication standards in Japan, the U.S., Canada, Thailand, Taiwan, Mexico, Vietnam, Brazil, Russia, and Malaysia. R-BT conforms to telecommunication standards in Japan, the U.S., Canada, the EU, Thailand, Mexico, Vietnam, and Russia. (Information valid as of September 2019.) For other countries and regions, please contact Tohnichi.

The HA/HAC/HACQSPDY series are compliant with ISO 6789:2017 starting January 2022. Calibration Certificates will be different from older products. American unit products are not compliant with ISO 6789:2017.

Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

Excel® is a registered trademark of Microsoft Corporation.

GLOBAL HOME

GLOBAL HOME