SUPPORT

SUPPORT

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Support from Tohnichi > Product Service

Product Service

Research and Development System

Torque equipment used as work tools are subject to a severe working environment in daily operation. To lessen the load placed on workers as much as possible, Tohnichi products are developed through the use of sophisticated ergonomic studies.

Tohnichi innovations resulting from this approach are lightweight tools made of titanium and aluminum, which are ideal for the growing numbers of elderly or female workers on the production floor.

Further, our ergonomically designed tool handles and other parts are enjoying increased popularity throughout all sectors of our clientele. Also introducing 3D CAD system and 3D-printer, Tohnichi develops the ergonomics designed hand tools.

Design and development by 3D CAD

Searching for user-friendly shape by using 3D printer

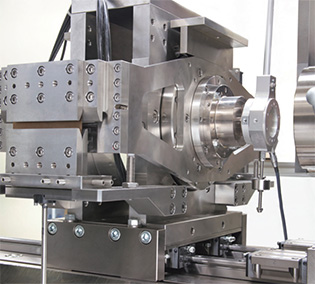

Durability Studies

While torque equipment requires high accuracy as a measurement device, it must also have sufficient ruggedness to ensure its performance as a work tool under severe conditions. In response, Tohnichi conducts research studies to help maintain the required levels of accuracy durability. (To learn more about torque tool accuracy and durability, click here.) Tohnichi endurance test room installs 10 machines, and operates the "type certification test" and "durability test" at the every new production development in order to assure accuracy and durability.

Durability test machine for torque screw drivers

Durability test machines for large, medium, and small size torque wrenches

Durability test machine for large size torque wrenches

Torque Measurement Studies

Tohnichi is conducting research and development into higher accuracy testers that can precisely determine the accuracy of torque measurement devices. By studying the mechanisms of decreased reliability in these torque measurement, we are working to establish a traceability system.

Calibration of reference standard torque wrench

Torque standard room

Calibration scene

Digital torque wrench tester JCSS calibration

Studies on Screw-Tightening Reliability

Tohnichi regularly conducts studies to enhance the reliability of bolt tightening. Notably, our studies on error-proofing (Pokayoke) techniques to prevent bolts from being left untightened have resulted in the development of FH-type wrenches and marking torque wrenches. These tools help operators to ensure that all bolts are tightened to the appropriate degree. Tohnichi has also developed a variety of checking devices designed to improve the reliability of tightening equipment. Moreover, we provide devices and software to allow management of tightening data on a computer.

Wireless transmitter development for error-proofing (Pokayoke) system

GLOBAL HOME

GLOBAL HOME