PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Tightening Assurance System > Tightening data control system for manual tools

Tightening data control system for manual tools

Our lineup includes torque devices that have proven their reliability in controlling torque. The lineup includes digital torque wrenches equipped with Bluetooth®, and click-type torque wrenches capable of wireless transmissions of tightening data.

CD5

CD5 compact display is a digital display that shows values measured by the strain gauge sensor. Based on judgment results, the display changes its color in white/red/blue.

Display for strain gauge sensor.

R-CM

Three different wireless modules can be used, and you can switch them on your own. They can be used on a number of different wireless devices, reducing cost.

Wireless Pokayoke (error proofing) torque wrench signal reception to prevent missed tightening

Wireless Pokayoke (error proofing) torque screwdriver signal reception to prevent missed tightening

Click type wireless data transfer torque wrenches FD/FDD and FDD-AD data reception

STC2-G / STC2-G-BT

Mounted multi-functional LED ring. Operator can visibly and audibly check the torque status and judgment.

For precise tightening and inspection.

For research and development electronic devices.

For daily check of torque screwdrivers.

The STC2-G-BT is ideal for cell production and the assembly of small lot orders.

TPC/TPC2

The protocol converter connects Tohnichi products to systems that have other configured protocols

It establishes a system that can use a variety of tools to match the output format of Tohnichi products with production line nutrunner protocols.

It establishes a system for converting the output of Tohnichi’s Pokayoke (error-proofing) R-CM receiver to Ethernet.

Nutrunner backup system

It provides torque control for nutrunner tasks in difficult-to-reach confined spaces.

It is used for preventing human tightening errors (Pokayoke) and managing tightening torque data.

TDMS/TDMSHT TDMS-C/TDMSHT-C TDMS-E/TDMSHT-E

Package software that helps standard values management and early error detection.

It offers labor-saving data entry and prevents input mistakes.

For managing the tightening and inspection data.

Re-tightening inspections.

Management of torque data in tightening work.

HA/HAC/HACQSPDY

For battery-charge type for excellent workability. Semi-automatic electric torque wrenches let you use your existing torque wrench tester for calibrating.

Cell production and assembly work on a sub-line

Tightening Data Management System

Provides evidence in the form of tightening torque data

R-BT

This Bluetooth receiver receives tightened-to-completion signals from the HAC series of battery-operated semi-automatic torque wrenches, and outputs signals to devices such as the CNA-4mk3 error-proof count checker. It can receive torque data from HACQSPDY devices that transmit tightening torque data, and from the PTA-BT series of battery-operated fully automatic torque drivers. Use it to easily build a tightening data management system.

Receives tightened-to-completion signals from battery-operated semiautomatic torque wrenches in the HAC series.

Tightening assurance system (Pokayoke) to prevent human tightening errors.

Tightening data management system using HACQSPDY or PTA-BT.

CES/CES-G

Torque measurement range: 0.5 ~ 10 N・m (*) Tohnichi’s smallest digital torque wrench (*two models in the series). The optional Bluetooth module makes it easy to manage data on a computer or other device.

For tightening and inspection work in low torque regions, such as cable grounding, and plastic or ceramic screws/bolts.

Useful in confined spaces and height-restricted locations where tightening with a torque screwdriver or conventional torque wrench is difficult.

For tightening work involving fragile apparatus, such as sensors and semiconductor manufacturing equipment.

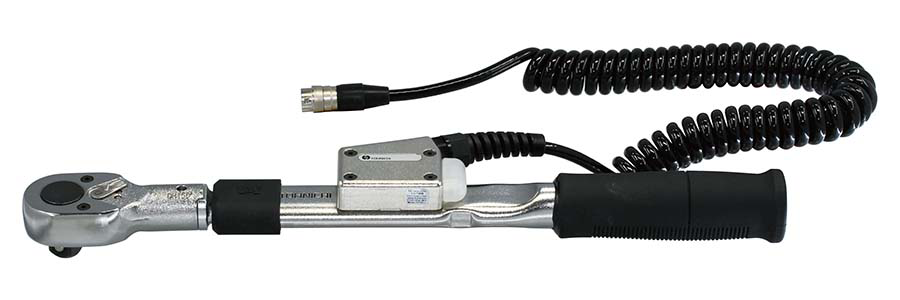

CSPLD

Tightening torque data captured when the wrench clicks at the set torque is transferred by cable. The Pass/Fail judgment is displayed on the body’s LED display for handy confirmation.

Tightening torque data management

Collects tightening torque data in work environments where an FD/FDD type of wireless torque wrench cannot be used.

CEM3-G-BTS/CEM3-G-BTD

Digital torque wrench with collected data wireless transfer function.

For inspection or tightening.

CEM3-WF/CEM3-G-WF

Digital torque wrench with wireless LAN communication functionality that conforms to the IEEE 802.11 standard. Use it to transmit data wirelessly in a wide variety of work areas.

Tightening tasks requiring recording and management of tightening data

Inspections requiring recording and management of tightening inspection data, for tasks such as retightening inspections

FD/FDD

Transmits tightening torque data wirelessly at the click moment. Pass/fail judgment is known close at hand, providing excellent workability. The FDD’s double tightening detection ensures even greater on-the-job reliability. The R-FHD receiver has been upgraded to the R-CM.

Tightening Torque Data Management

Pokayoke (tightening error-proof)

FDD-AD

Tightening torque and angle data are transmitted automatically at the audible “Click!” moment. Precision Pass/Fail judgments ensure a higher level of tightening reliability.

Tightening Torque Data Management

Pokayoke (tightening error-proof)

Detects two rounds of tightening to prevent this human error (Pokayoke).

Detects increased torque due to insufficient rotations from “biting (seizure)” during tightening.

FHD256

Ideal for tightening torque traceability system. Order acceptance of FHD256 ends on March 31, 2016. The successor model is FD/FDD.

Tightening Torque Data Management

FHDS256

Comes with compact transmitter for excellent workability. Ideal for tightening torque traceability system. Order acceptance of FHD256 ends on March 31, 2016. The successor model is FD/FDD.

Tightening Torque Data Management

CEM3-G-BTA

Also able to detect double tightening and “bite.” Digital torque wrench measures both torque and angle, and is Bluetooth(R) equipped for advanced pass/fail judgment.

GLOBAL HOME

GLOBAL HOME