PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Power Torque Tools > Power Torque Screwdriver > PTA-G-BT

PTA-G-BT

Assembly

PISTOL TYPE

Electric Power

Direct input type

Judgment

Re-chargeable

For labor-saving and high-accuracy tightening. Permits management of entire tightening torque data.

PTA10N-G-BT

Left: Pass/Fail judgment: OK Right: Pass/Fail judgment: NG (No Good)

Torque checking example using digital torque wrench tester

Left: Battery pack Right: Charger

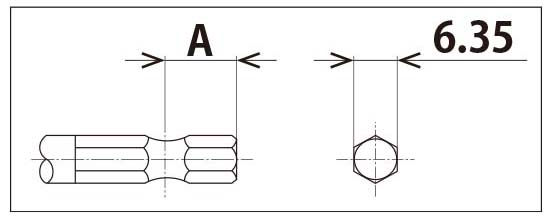

Can be used when bit length at A is between 9 and 14 mm, and distance between hex flats is 6.35 mm.

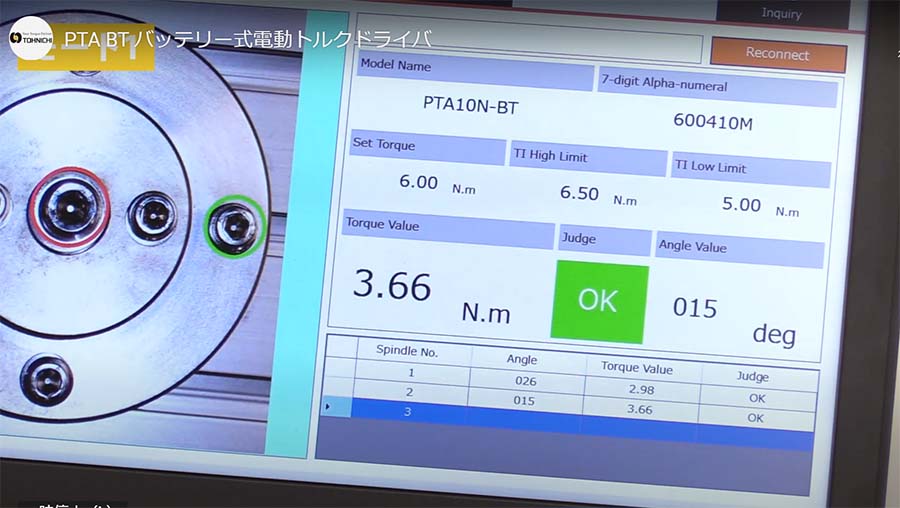

[Free Gift] Customers who purchase PTA-BT will receive the PTA-BT tightening control software used in the video below from 2:14 to 3:16. [Software Overview] Switchable between Japanese/English, PC sends tightening conditions to the tool, and after tightening, the results are sent from the tool to the PC. Up to nine different tightening conditions can be registered for one work (up to two different types of work). The software displays a picture of the customer's work, allowing the user to visually check the work order, etc. Up to two types of tools can also be registered, so that models with different torque ranges or tools with different sockets are also supported. Imported tightening data can be exported in CSV format. *This software cannot be downloaded.

Application

- Labor-saving for tightening tasks from 2 to 10 N·m. * Two models in the series.

- Automatic retrieval of tightening torque data reduces task load and prevents entry errors.

- Detects two rounds of tightening to prevent this human error (Pokayoke).

- Detects torque increase in insufficient rotation angles caused by “biting (seizure)” or the like during tightening.

- Terminal block tightening operations. Terminal block screws: M5/M6 (PTA5N-BT) or M6/M8 (PTA10N-BT) * For tightening torque values, check the spec. sheet etc. provided by the terminal block manufacturer.

Features

- Just pull the trigger of the PTA-G-BT for fully automatic tightening.

- Comes with built-in torque sensor and angle sensor. Torque precision: ±5%. Angle precision: ±5°

- Measures torque and angle values to determine PASS or FAIL. Can detect tightening abnormalities such as thread fouling and internal thread defects, and can also detect double tightening (Pokayoke (error-proofing)).

- Tightening torque upper and lower limits and angle can be set using the key-in function on the body, or through Bluetooth® connectivity. *Download setting software from “Download” at the bottom of the screen, then > “Software.”

- Purchase this at a low cost and already start using it. Why opt for a high-priced dedicated controller?

- Can transmit tightening data via Bluetooth® technology. * Use Excel® on your computer to manage data received via the DtRcv (Data Receiver). DtRcv is included in software under the screen.

- The torque wrench tester makes it easy to verify torque.

- Low noise, low vibration, without the pulsating sound or vibrations of an impact wrench. See spec sheet for numerical values.

- CO2 emissions are 97% lower than conventional models (Tohnichi pneumatic AUR series).

- PTA-G-BT conforms to wireless technical standards in Japan, the EU, Thailand, Malaysia, Indonesia, India, and China. (Information valid as of July 2021.) However, certain restrictions apply regarding export procedures to Indonesia, so please check with Tohnichi for more information.

- [Free Gift] Customers who purchase PTA-BT will receive the PTA-BT tightening control software used in the video below from 2:14 to 3:16. [Software Overview] Switchable between Japanese/English, PC sends tightening conditions to the tool, and after tightening, the results are sent from the tool to the PC. Up to nine different tightening conditions can be registered for one work (up to two different types of work). The software displays a picture of the customer's work, allowing the user to visually check the work order, etc. Up to two types of tools can also be registered, so models with different torque ranges and tools with different sockets are also supported. Imported tightening data can be exported in CSV format. *This software cannot be downloaded.

Demonstration video

Tohnichi production information: PTA-G-BT battery type fully automatic electric torque screwdriver

Specifications

[N・m] |

||||

[kgf・cm] |

||||

[lbf・in] |

||||

[ r.p.m. ] |

||||

[ dB ] |

||||

[ m/s2 ] |

||||

Notes

Turning the PTA-BT/PTA-G-BT counterclockwise is for loosening operations only, and cannot be performed for torque management.

Battery pack and charger not standard accessories. Purchase from one of the dealers listed separately, taking into account your intended use.

Under Japan’s Measurement Law, PTA-G-BT series devices cannot be used in Japan or sold for use in Japan.

Excel is either a registered trademark or a trademark of Microsoft Corporation in the United States and other countries.

Optional Equipment

Accessories

Download

Software

Japanese English Chinese German

Parts List

Japanese English Chinese German

Online Part Search System

Japanese Worldwide

GLOBAL HOME

GLOBAL HOME