PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Torque Wrench > Click Type Torque Wrench > Adjustable Torque Wrench > QL/QLE2

QL/QLE2

Assembly

Adjustable

Ratchet Head

Torque Graduation

Sets the global standard for adjustable torque wrenches used to tighten bolts

QL10N [Overall length 219 mm]

Color cap

Color cap

Color cap

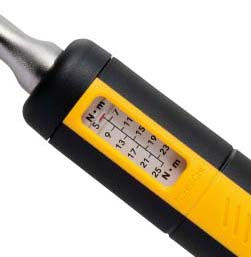

QL25N5 Scale

QL50N [Overall length 258 mm]

QL100N4 [Overall length 333 mm]

QL140N [Overall length 399 mm]

QL200N4 [Overall length 489 mm]

QL280N [Overall length 692 mm]

QL420N [Overall length 993 mm]

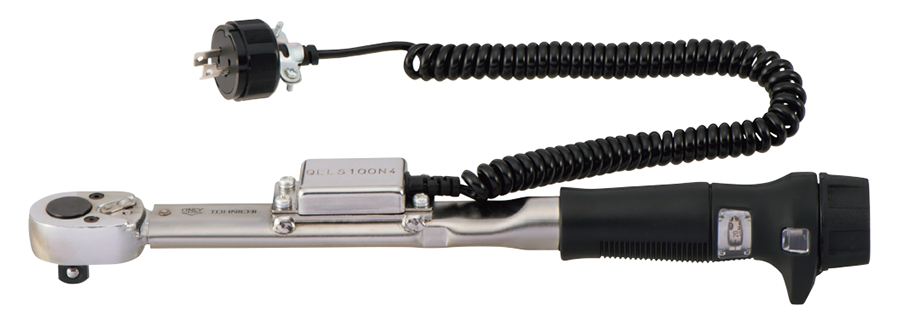

QLE2100N2 [Overall length 1899 mm]

QLE2100N2 [Overall length of the unit 1103 mm, Extension handle 911 mm]

Torque setting by a built-in handle

Features

- Basic shape of a torque wrench for tightening operations

- A clear “click” sound signals tightening completion upon reaching the set torque.

- The ratchet head has 24 teeth with a 15 degree operating range, allowing for use in space-limited working conditions.

- Torque setting is easy to adjust by knob and scale.

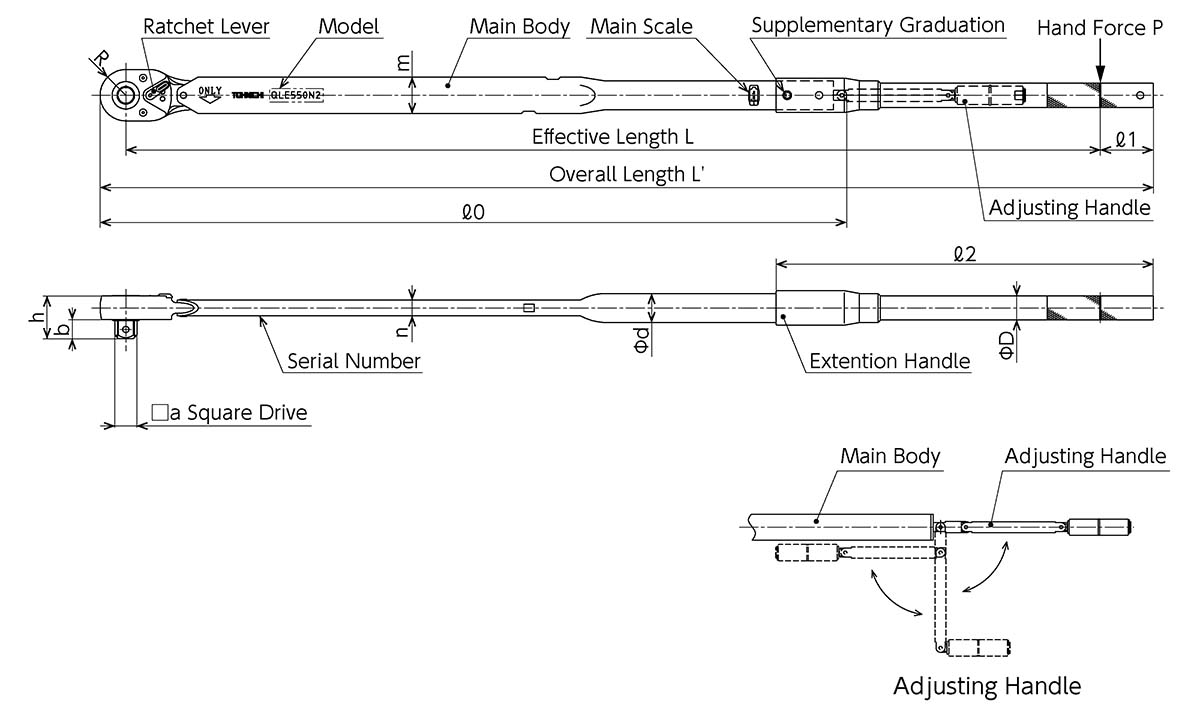

- With QLE550N2 to QLE2800N2 models, the built-in torque adjustment handle makes torque changes easy even without a special-purpose tool.

- QL2N to QL25N5 models have a resin grip with a large, clear built-in scale.

- QL50N to QL280N models have a resin grip, while the QL420N has a knurled metal handle.

- QLE550N2 to QLE2800N2 models have an extension handle that separates from the body for compact storage.

- Except for some products, the QL/QLE2 series are compliant with ISO 6789:2017 starting January 2022. For more information, see the technical data “Initiatives for ISO 6789:2017” at the bottom of the screen.

Specifications

[N・m] |

|||||||||||

[Kgf・cm] |

|||||||||||

[lbf・in] |

|||||||||||

[mm] |

|||||||||||

[N・m] |

|||||||||||

[Kgf・ cm/Kgf・m] |

100~500 |

4~28 |

|||||||||

5 |

0.2 | ||||||||||

RANGE [lbf・ in/lbf・ft] |

100~400 |

15~75 |

|||||||||

5 |

1 |

||||||||||

[mm] |

|||||||||||

[N・m] |

|||||||||||

[Kgf・m] |

|||||||||||

[lbf・ft] |

|||||||||||

[mm] |

|||||||||||

Notes

Use a through-hole socket (for power tools) for a square drive of 25.4 mm or larger.

SI unit products (except QL2N and QL5N) and metric unit products (except 20QL and 50QL) are compliant with ISO 6789:2017 starting January 2022. Calibration Certificates will be different from older products. American unit products are not compliant with ISO 6789:2017.

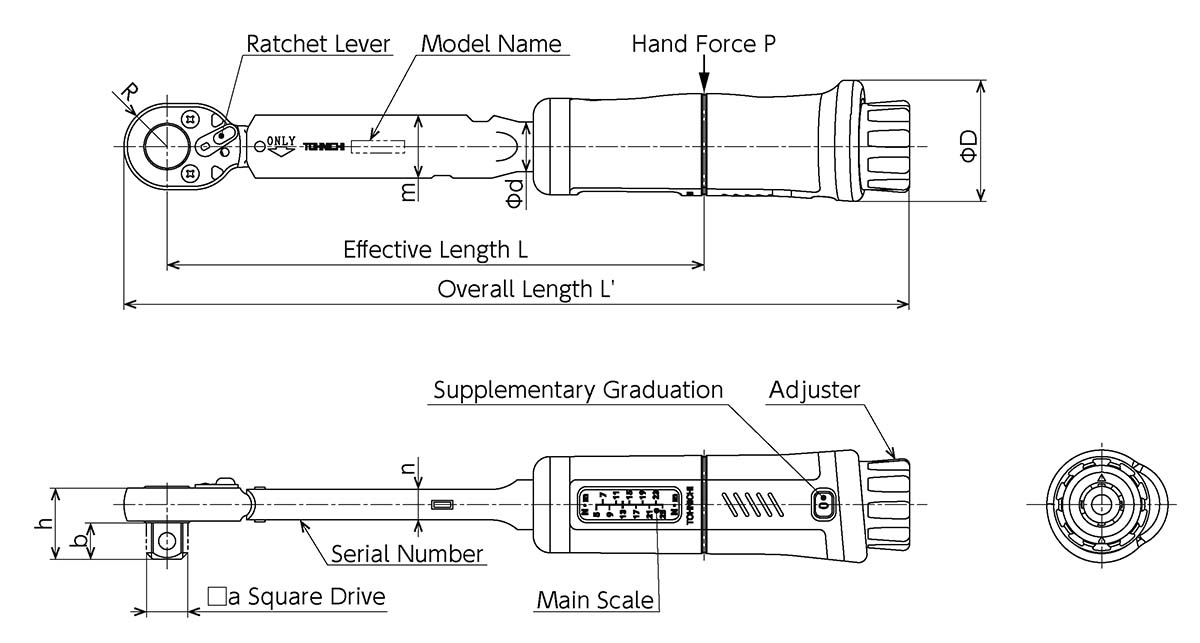

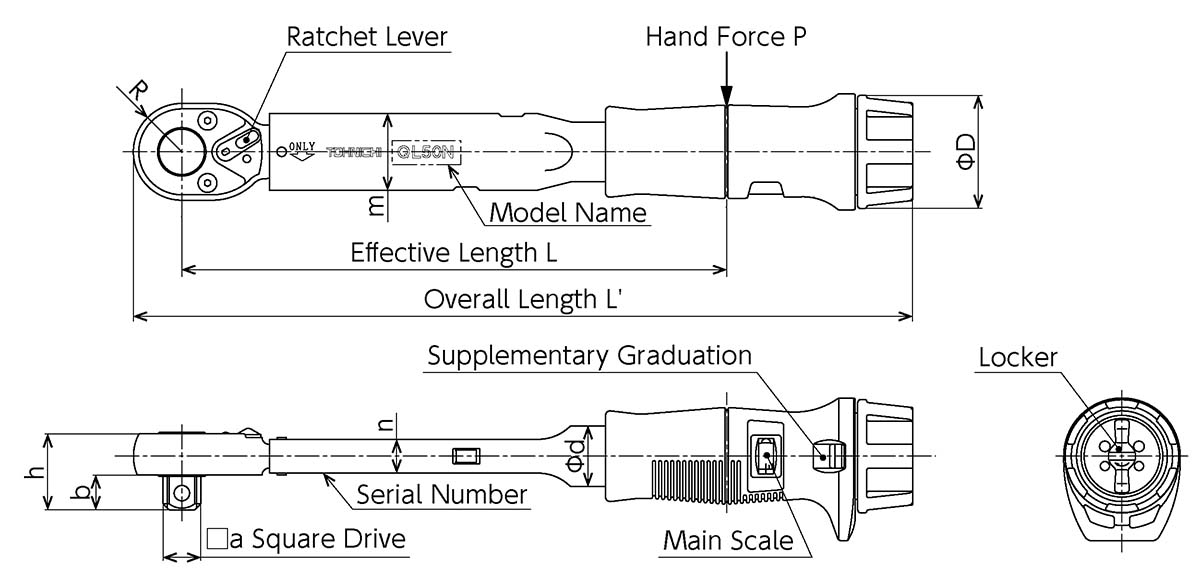

Dimensions

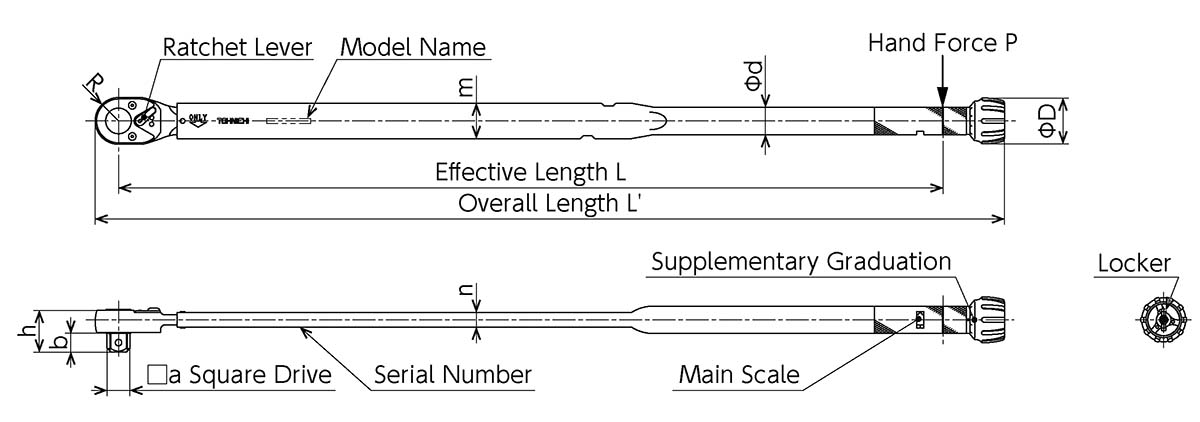

QL2N~25N5

QL50N~280N

QL420N

QLE5502N2~2800N2

◆ How to order

[Tohnichi] [Model] Please specify.

[Example] Tohnichi QL25N5

◆ Things to remember when ordering

Not available for inspection purposes.

For models with limit switch designed to prevent human tightening errors, refer to QLLS/CLLS/PQLLS/PCLLS/TiQLLS.

Testers, checkers, calibration kits

Download

Product Catalog

Japanese English Chinese German

Software

Japanese English Chinese German

Parts List

Japanese English Chinese German

How to Use

Applying the correct force/Loosening tasks/Tightening left-handed bolts and screws

[March 2025 Version] Tohnichi’s Torque Engineering Seminars, ready to provide positive results in the workplace right away.

Japanese English Chinese German

Tohnichi torque product information: Automobile maintenance

Japanese English Chinese German

Tohnichi torque product information: Plant construction

Japanese English Chinese German

Tohnichi torque product information: Railroad

Japanese English Chinese German

Tohnichi Torque Devices for Aviation Industries

Japanese English Chinese German

GLOBAL HOME

GLOBAL HOME