PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

TW2

Assembly

Adjustable

With multiplier

Graduation

Bi-Direction

Stand-alone torque wrenches for easy and accurate tightening of wheel nuts for large vehicles such as trucks, tractor-trailers and buses; it also only requires one person to use it, helping to cut down on labor costs.

TW1000N2

Before, two workers were needed for use of the large DQLE torque wrench: one to support the wrench head and ensure alignment with the nut location, the other to operate the wrench.

With the TW2, easy and accurate torque control for the wheel nuts of large vehicles can be done with just one worker, reducing labor costs.

After a tire change, retightening can be done by just one worker at the transportation company’s branch office or sales office located about 100 km away.

Application

- For tightening wheel nuts of large vehicles

- Retightening wheel nuts of trucks, tractor-trailers, buses, etc. (torque control)

- Tools requiring less physical strength

- Even for tightening centerlock nuts on the hubs of racing cars and sports cars (e.g., Porsche 911 GT3).

Features

- The TW2 series are large stand-alone torque wrenches. Tasks that generally require two operators can be done with just one.

- The built-in mechanism multiplies force about 3 times, making it suitable even for tightening wheel nuts on large trucks. Therefore, less physical strength is required.

- Adjusting tightening position is free by damper.

- The unique caster layout offers freedom of access to the job at hand.

- Less cost without any power source.

- Power source (pneumatic or electrical) not required.

- Torque checking and tightening can be performed easily at the same time with the SPINTORK ST1000N3.

- ±5% precision. Supports clockwise and counterclockwise operation. Patented.

- The TWMS-KIT is an upgrade of the familiar TW2 Series to TWMS standards.

Specifications

[N・m] |

|||||||||

Notes

Interchangeable sockets, pins and O-rings (to prevent dropout) are not supplied.

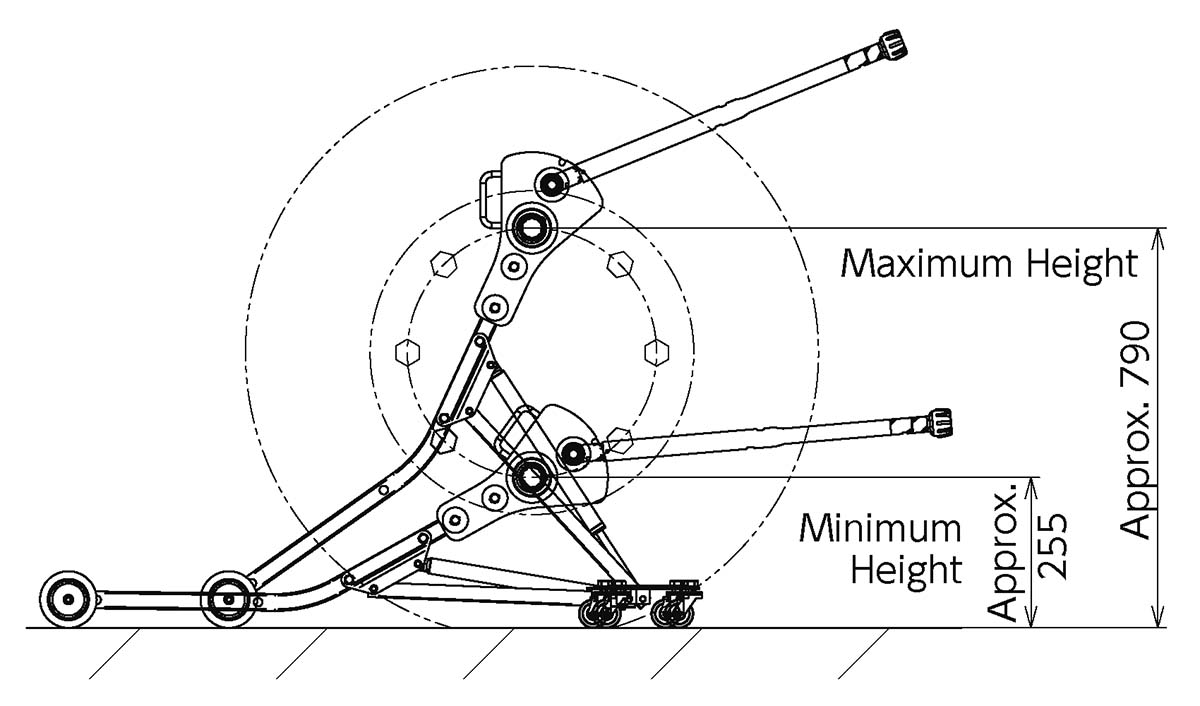

Permissible height of nut position: approx. 250 to 800 mm above ground.

Use a through-hole socket (for power tools) for a square drive of 25.4 mm or larger.

Standard accessory

Calibration Certificate, User’s Manual

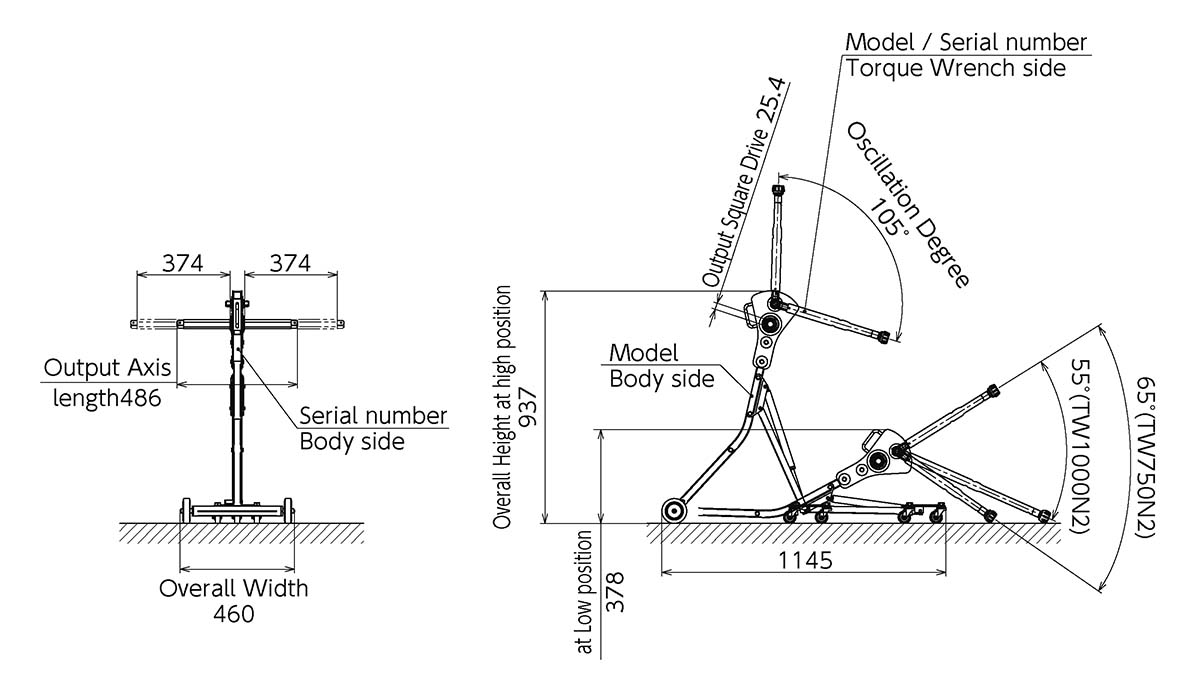

Dimensions

TW750N2,TW1000N2

Available bolt position

◆ How to order

[Tohnichi] [Model] Please specify.

[Example] Tohnichi TW1000N2

Download

Software

Japanese English Chinese German

2D CAD (DXF)

Japanese English Chinese German

3D CAD (IGES)

Japanese English Chinese German

Parts List

Japanese English Chinese German

GLOBAL HOME

GLOBAL HOME