COMPANY

COMPANY

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Company Information > Brand Regulations > Tohnichi Craftsmanship provides products with high quality.

For various kinds of small quantity production –Tohnichi craftsmanship provides torque products with high quality

Tohnichi provides a large variety of torque equipment. There are hundreds of torque wrenches in our catalogue and more than 10,000 kinds of specialty models.

We respond to our customers who desire tightening and measuring work effectively and ideally.

High Quality Tohnichi products are produced from our factories in Omori Tokyo, Kofu Yamanashi and Tsukuba Ibaraki.

Omori Factory

Our Omori Factory in Ota-ku, Tokyo assembles mainly electrical and digital products and measuring devices, including: the TF series of fully automatic digital torque wrench testers; the CEM3-BT/CEM3-G-BT series of Bluetooth-equipped digital torque wrenches; and the STC2(-BT)/STC2-G(-BT) series of digital torque screwdrivers.

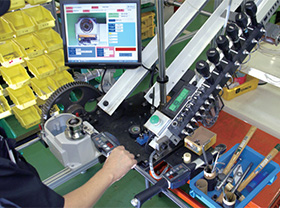

When Tohnichi’s torque wrench testers are assembled, each one is subjected to strict Pokayoke (error proofing) methods using our company’s own RNTDFH wireless Pokayoke torque screwdrivers. In addition, we’ve constructed a tightening guarantee system to measure and control tightening torque data, and use it during manufacturing processes.

Tightening Assurance System at Omori factory

Kofu Factory

Our Kofu factory in Kofu, Yamanashi Prefecture has a good view of Japan's Southern Alps. It is Tohnichi’s key center for the machining and assembling of mechanical torque wrenches and torque screwdrivers. Tohnichi’s production system uses “Kanban” methods which adapt flexibly for manufacturing a wide range of products made to order, some in small lots, some in the tens of thousands. The factory’s machining shop has all-purpose MC equipment and unique machinery (such as an automated press for torque wrench tubes) for top-of-the-line mass production. Its assembly facility has more than 30 pieces of precision equipment. These include devices for torque measurements of torque wrenches and torque screwdrivers during the assembly process, for calibrations in the inspection lab using a fully automated TF series digital torque wrench tester, and a TDT3/TDT3-G digital torque screwdriver tester. All ensure traceability, and are used to control Tohnichi production.

Measuring Torque Value of Torque Driver

Machine Pressing for Torque Wrench

Measuring Torque Value in Assembling Process

Calibrating QLE model at Inspection Room

Tsukuba Factory

The Tsukuba factory in Ibaraki specializes in the machining processing, making Tohnichi interchangeable heads, parts of QSPCA models and others. Likewise, it has milling machines and hobbing machines, and the inspection for dimensions and hardness of products is also performed there.

Hob Machining Unit for Gear Cutting

GLOBAL HOME

GLOBAL HOME