PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Power Torque Tools > Power Torque Wrench > AP2

AP2

Assembly

PISTOL TYPE

Pneumatic

Graduation

Trigger/Lever

Pneumatic heavy duty nut runners for large bolt application.

Features

- Automatic gear shift mechanism allows high speed provisional tightening, and low speed tightening to completion to maintain stable tightening operation.

- Torque remains stable regardless of air fluctuations.

- Torque setting is easy to adjust by knob and scale.

- When set torque value is achieved the residual torque easing mechanism causes the body to reverse direction slightly, making it easy to attach and detach sockets.

- Reaction arm is designed to absorb the reaction force, which assures safe operation even when the operator is working in difficult position.

- Reaction arm can be positioned freely to allow flexibility in position setting.

- We can also manufacture Pokayoke (error-proofing) products that receive tightened-to-completion signals. (Please contact us since product would have made-to-order-specs)

- The AP series became the AP2 series in March 2017, and durability was improved significantly.

Specifications

[N・m] |

||||||||

[kgf・m] |

||||||||

[lbf・ft] |

||||||||

BOLT |

||||||||

[mm] |

||||||||

(Optional accessory) |

||||||||

Standard accessory

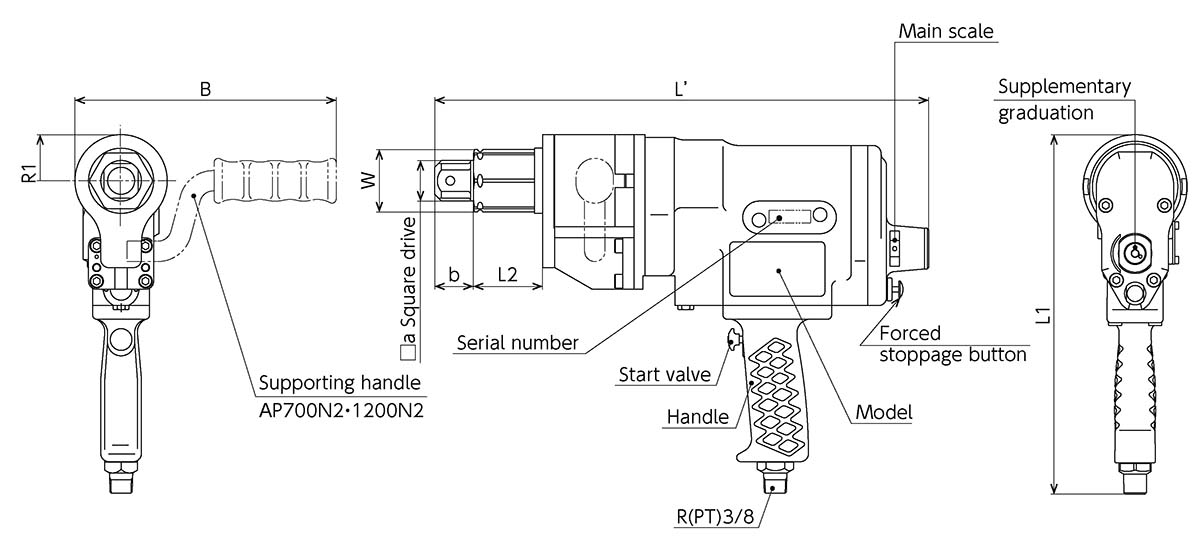

W5 hex key. Supporting handle (only for AP700N2, and 1200N2).

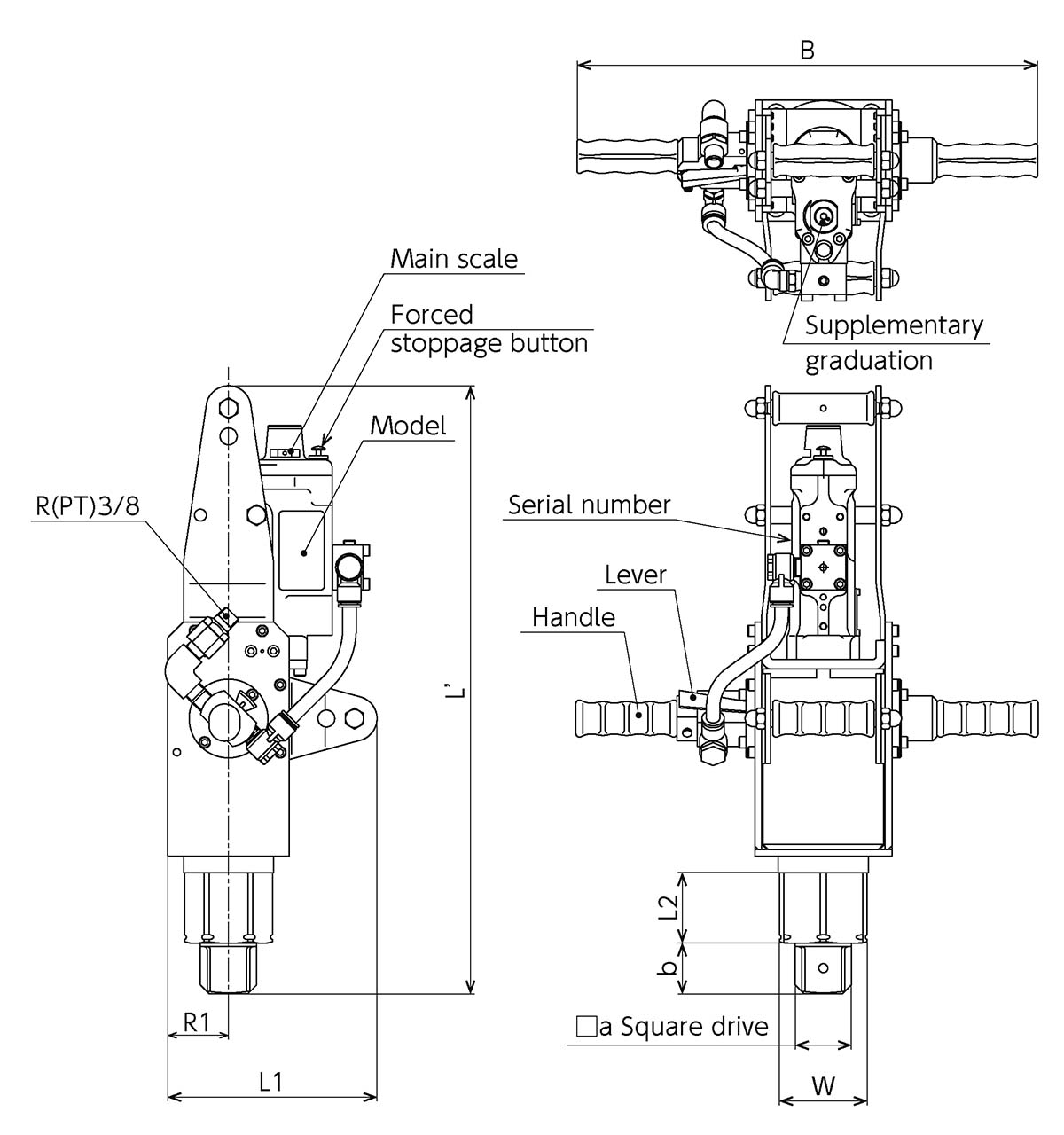

Dimensions

AP220N2~1200N2

AP2200N2, 4000N2

◆ How to order

Specify Tohnichi, model, and reaction arm (UA, SA).

[Example] Tohnichi AP400N2+UA450N

◆ Things to remember when ordering

Cannot be used without reaction arm.

Use pneumatic sockets only.

Optional Equipment

Testers, checkers, calibration kits

Download

Product Catalog

Japanese English Chinese German

Software

Japanese English Chinese German

Parts List

Japanese English Chinese German

GLOBAL HOME

GLOBAL HOME