PRODUCTS

PRODUCTS

English

Use accurate torque controls to improve quality! Case examples can be found in torque handbook 10

HOME > Products > Multiple Unit > Multiple Unit > ME/MC2

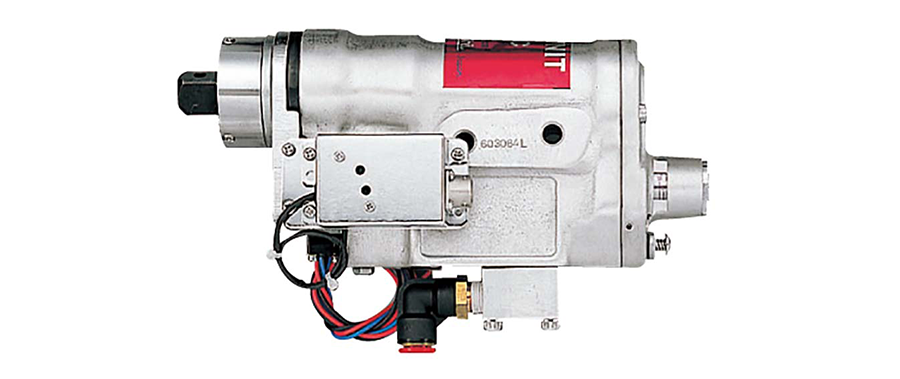

ME/MC2

For automatic tightening equipment

Straight

Pneumatic

Graduation

Master Valve Operation

For automation of multi-spindle tightening with a wide range of screws (M8 to M48).

Features

- Automatic gear shift mechanism allows high speed provisional tightening and low speed tightening to completion, to maintain stable high-precision tightening operation.

- Torque remains stable regardless of air pressure fluctuations, since torque control is performed mechanically.

- Torque setting is easy to adjust by knob and scale.

- When set torque value is achieved the residual torque easing mechanism causes the body to reverse direction slightly, making it easy to attach and detach sockets.

- Upon reaching the set torque, the internal toggle clicks and automatically stops operation, while the micro switch turns on simultaneously to signal tightening completion.

- Signal indicating tightening to completion eliminates missed tightening.

- Attach torque sensor (sold separately) for double-check pass/fail judgment (mechanical and electronic).

- The MC series became the MC2 series in March 2017, and durability was improved significantly.

Specifications

[N・m] |

||||||||||||

[kgf・cm/kgf・m] |

100 - 250 |

10 - 22 |

||||||||||

5 |

1 |

|||||||||||

[lbf・in/lbf・ft] |

90 - 220 |

35 - 90 |

||||||||||

5 |

2 |

|||||||||||

[mm] |

||||||||||||

Notes

Includes auto-reverse/auto-reset functions.

For dimensions of air connecting part, refer to P.359

Standard accessory

Scaled set rod (ME), W5 hex key (MC2)

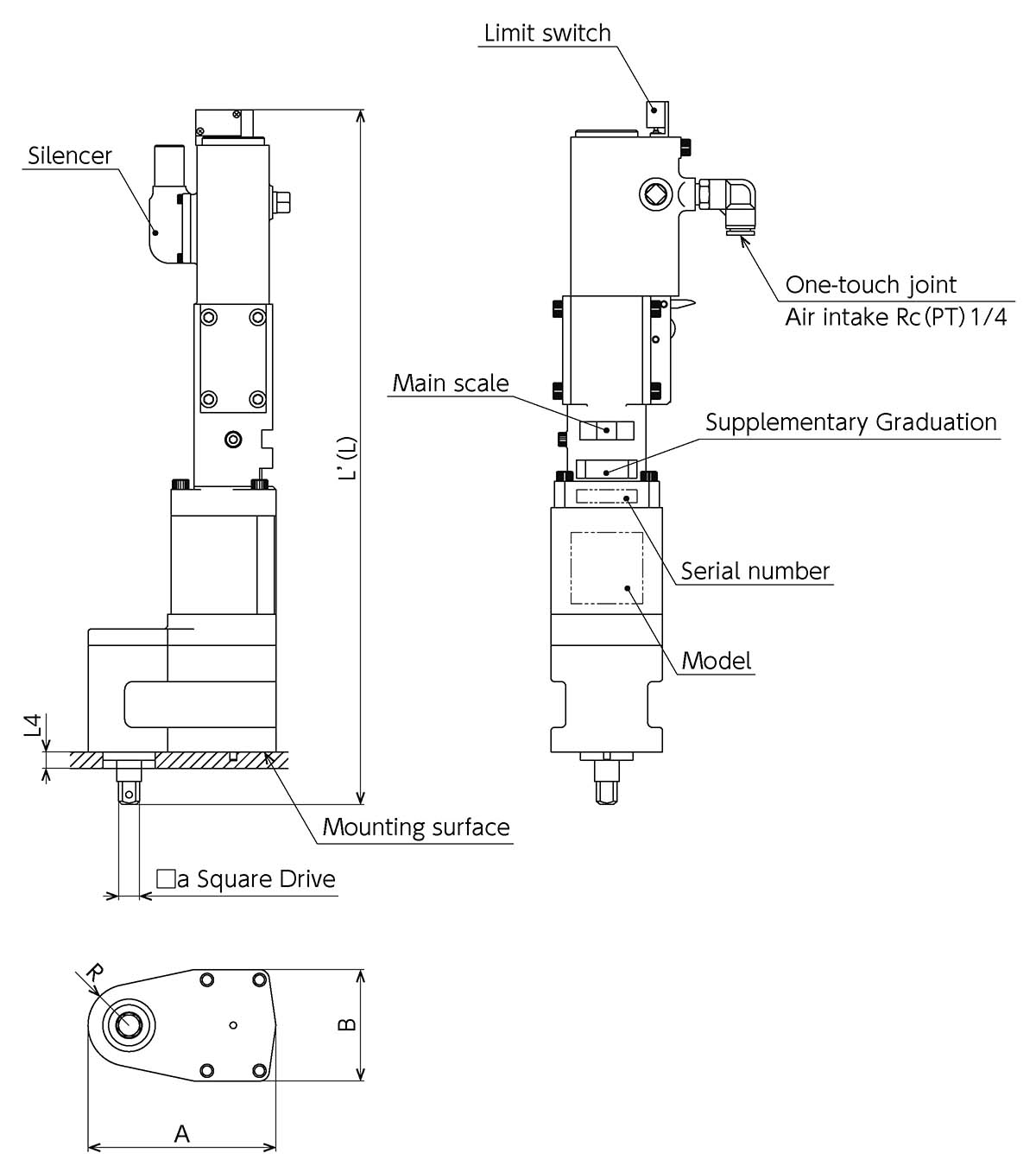

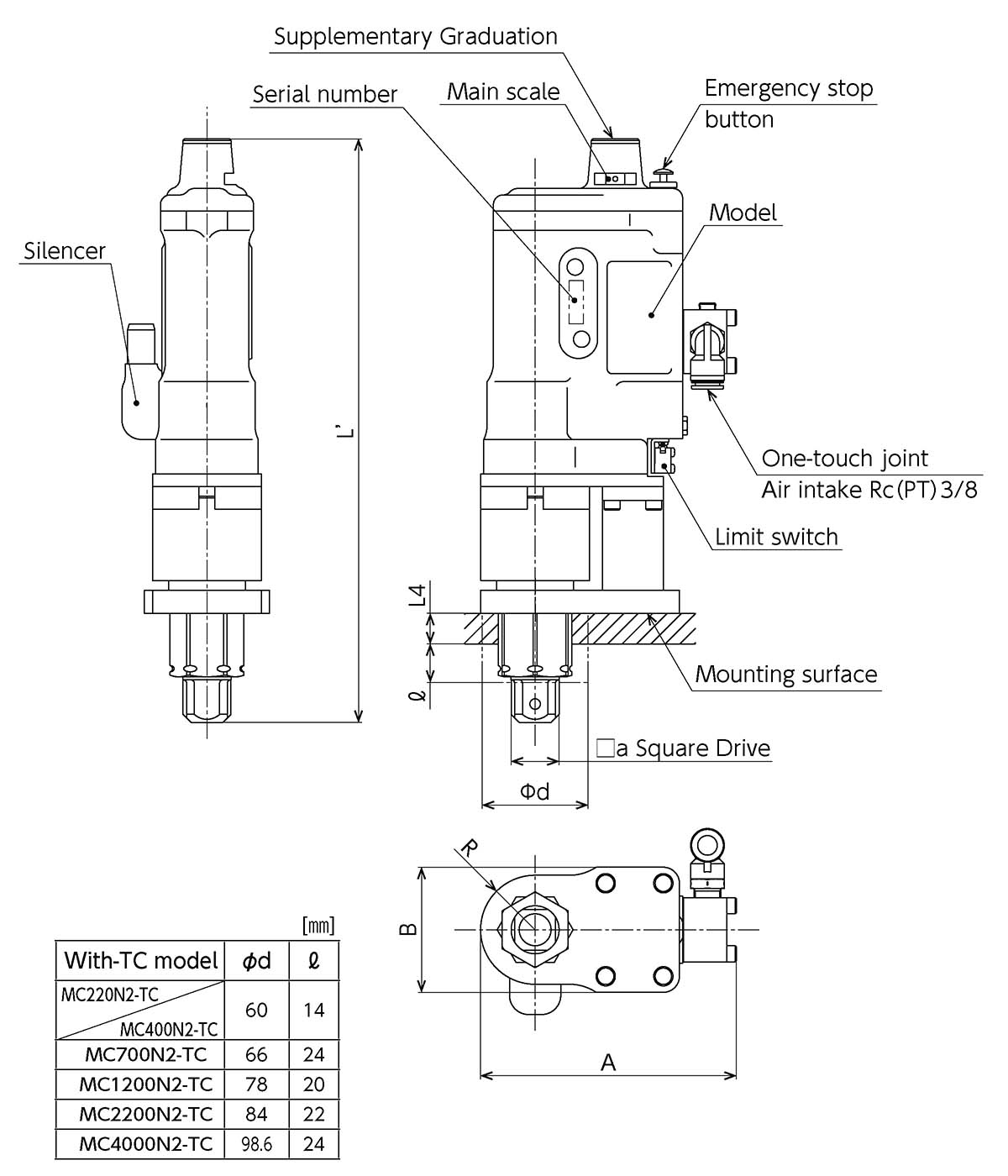

Dimensions

ME

MC2

◆ How to order

[Tohnichi] [Model] Please specify.

[Example 1] Tohnichi ME80N

[Example 2] Tohnichi ME80N-TC

◆ Things to remember when ordering

For designing a multi-spindle nut runner, check the minimum distance between the spindles, or PCD.

Add ‒TC for sensor-equipped version. [Example 2]

Refer to guidelines for multiple unit installation.

For first-time users, contact Tohnichi or our nearest distributors.

Accessories

Testers, checkers, calibration kits

Download

Product Catalog

Japanese English Chinese German

Software

Japanese English Chinese German

Parts List

Japanese English Chinese German

How to Use

Things to look out for when handling multi-spindle equipment, and mounting dimensions

[March 2025 Version] Tohnichi’s Torque Engineering Seminars, ready to provide positive results in the workplace right away.

Japanese English Chinese German

GLOBAL HOME

GLOBAL HOME